Leak Shooter

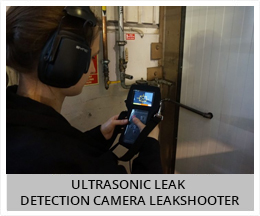

1st ultrasonic compressed air, gaz and vacuum leak detector with camera. Specialy dedicated to visualize the spots where compressed air is leaking, the LEAKSHOOTER LKS 1000 – V.2 has many other applications such as : steam trap monitoring, bearing monitoring, electrical applications like partial discharge, corona effects, punctured isolators, electrical tracking detection.

Compressed air is a costly form of energy and 20 to 40 % of it is lost through leaks. Systematically checking for and eliminating leaks can therefore bring considerable energy savings. With LEAKSHOOTER it is extremely simple and easy to locate rapidly leaks because they are immediately visible on the screen whille you’re hearing at them.

The LEAKSHOOTER LKS 1000-V.2 is a sophisticated tool. Extremely sensitive, it is capable of finding all leaks even the smallest, including those no bigger than the size of a syringe needle, at a distance of 15 metres.

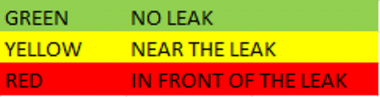

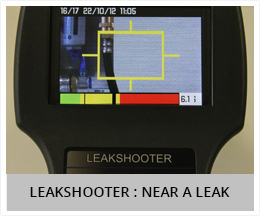

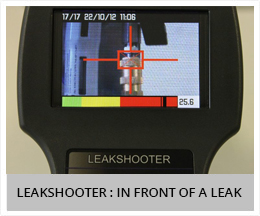

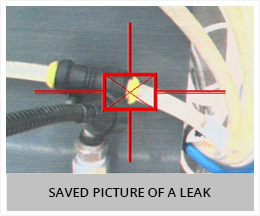

The LEAKSHOOTER LKS 1000- V.2 is used like a camera. When it comes near a leak, a dynamic yellow target appears on the large colour screen. The target turns red and shrinks as it approaches the source of the leak. A bar graph at the bottom of the screen accompanies and facilitates the search. When the device is facing the leak, a cross appears in the center of the target. It is then possible to photograph and save the precise location of the leak.

Each photo is numbered, dated and timed, and shows the dB RMS level of the leak with the level of the gain setting. The photos can be uploaded directly onto a PC via a USB cable (supplied).

It is still possible, whilst visually searching for a leak, to listen to the hissing sound of the leak using the professional headphones supplied with the device. The leak detection becomes then extremely user-friendly since you see what you’re listening to.

Standard kit includes

- LEAKSHOOTER LKS 1000-V.2 camera

- Professionnal headphones

- Battery charger

- USB cable

- Instructions of use

- 2 years warranty certificate

- Quality control certificate

- Carrying case

Technical datas

| Sensitivity |

Detect a leak of 0.1mm at 3 bars at 20m |

| Camera |

Colour 640x480 pixels |

| Display |

LCD colour 3,5" 320x240 pixels |

| Pictures |

BMP, number, date and time |

| Dynamic Target |

- Red square with cross on strong leak - Yellow square with cross on light leak |

| Measurements |

dB RMS and MAX |

| Memory |

Up to 1000 pictures, can be uploaded to PC |

| Communication |

USB cable supplied |

| US sensor |

- Open type - Bandwidth +/- 2kHz à -6 dB - Central frequency 40kHz +/- 1kHz - Adjustable frequency mixer from 34 to 46 kHz - Auto gain, and adjustable from 50 to 110 dB |

| Headset |

Adjustable volume from 0 to 10 |

| Power supply |

Lithium-ion rechargeable battery |

| Autonomy |

6 hours |

| Temperature range |

-10°C to + 50°C |

| Dimensions |

230mm x 100mm x 70mm |

| Weight |

580g LKS1000 alone, with metallic case 3,9 kg |

| Standards CE |

CEM 2004/108/CE: EN61000-6-4 & EN61000-6-2 |

| Accessories |

-For steam trap and bearing control LKSPROBE ultrasonic probe -Flexible probe for hard to reach areas LKSFLEX (400 mm long) LKSFLEX1500 (500 mm long) -For tightness testing LKS DOME Ultrasonic generator with 13 emitters -For the LEAKSHOOTER protection LKSCOVER |