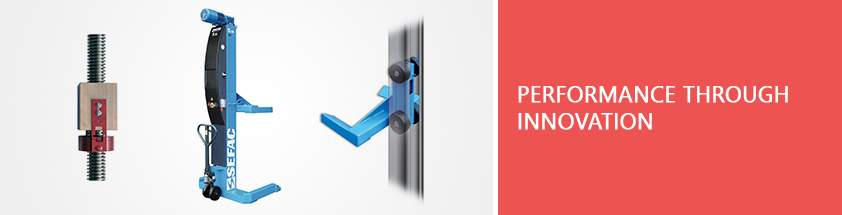

PMX and PMZ

Safety use!

This technology does not require the addition of any safety devices like toothed rack, preventing access to the lifted vehicle.

Moreover, you choose your lifting height with a millimetric precision in full safety (no predetermined position caused by the notches of the safety latch device).

Performances

Flexibility and versatility!

Excellent speed/precision ratio: up to 600 mm/min

Lift of any heavy duty vehicle. Capacity per column: 5.5 or 8.2 tons

Adaptation to new standards

Innovative evolution!

The new mechanical architecture of SEFAC columns includes high-density polymer bearing rollers circulating inside channel beams. It also complies with the multi-axis systems and with the new EURO5 standard.

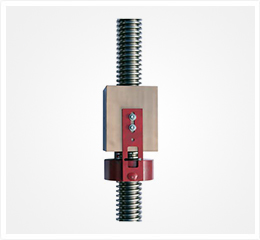

Quick removal

Fast maintenance!

No oil nor seals to replace, no level to check or regular bleedings to carry out: an innovative system of quick removal of the single wear part (phosphor bronze nut) enables the carrying out of replacement in less than 15 minutes. The cold-rolled lifting screw, combined with a new revolutionary safety nut, reduces the maintenance on these components to a bare minimum.

At the top of the technology

Shared intelligence!

We use a standard programmable relay, to ensure the user an easy, reliable and effective control of the mobile columns.

Technical specification

| Features | PMX | PMZ | |

| Capacity per column | tonne | 5,5 | 8,2 |

| Operating mode | - | single/pair/group (4, 6 or 8) | single/pair/group (4, 6 or 8) |

| Control | - | Pendant | Pendant |

| Performances | PMX | PMZ | |

| Tire size | inch | 8.25 R 20 to 13.00 R 22.5 | 8.25 R 20 to 13.00 R 22.5 |

| mm | (Ø 962 - 1 154) | (Ø 962 - 1 154) | |

| Lifting speed Up | mm/min | 500 | 680 |

| Lifting speed Down | mm/min | 500 | 680 |

| Lifting height | mm | 1 820 | 1 820 |

| Dimensions | PMX | PMZ | |

| Overall (l x L x h) | mm | 1 045 x 1 040 x 2 540 | 1 050 x 1 125 x 2 540 |

| Leg height | mm | 135 | 135 |

| Net weight per column | kg | 335 | 385 |

| Motor power | kW | 2,2 | 2,9 |

| Dust water protection level | - | IP55 | IP55 |

| Sound level | dB | <75 | <75 |

Quality for performance

Mobile columns lifts for heavy duty vehicles feature undeniable advantages in terms of safety, ergonomics and extra space.

With its S1 and S3 columns, SEFAC offers a wide range of technologies and innovations to make your life easier.

- Durability :

Use of standard industrial components (PLC); - Quality :

Assembly by dedicated welding robot as per ISO3834-2/3 standard; - Reliability :

Burn-in of each column with static and dynamic load tests; - Flexibility :

Non-reversible screw and nut system which built up SEFAC's reputation.

Thanks to a technical expertise based on a manufacturer's know-how of nearly 40 years, our R&D team continuously anticipates the needs of our clients. That is why S1 and S3 SEFAC columns are the subject of many patent applications both in France and abroad.

S1 and S3 SEFAC columns comply with the 2006/42/EC European directive and the EN1493 standard (type EC certification) and meet the most stringent EMC level.

Certifications

- Type EC

- ANSI/ALI/ALCTV-2006

- GOST

- ANSI/UL 201-2005

The service direct from the manufacturer

For servicing your mobile columns, with just a phone call, you can at any time benefit from the intervention of our local service engineers.

- Efficiency and quick response

- Possibility to exchange your old mobile column lift;

- Load tests on our calibrated test bench;

- Service formulas adapted to your needs.